Contec and Wilson sleeves are virtually identical. Here is a breakdown of their similarities, dimensions and other technical information.

Similarities

- Both the Contec Anchor Sleeve and the Wilson Anchor Sleeve are manufactured from non-conductive and non-rusting high-impact polyethylene plastic.

- Both sleeve types are light weight with thick plastic walls strong enough to support the weight of concrete used in their application.

- Both sleeve types have ribs that lock with the hardened concrete and provide additional resistance to pull out, especially when compared to a normal grout pocket.

- Neither sleeve type should be used in any situation where extreme temperatures are present. Both sleeves warn against high temperature applications.

- Both sleeves are made to be used with a specific diameter or diameters of anchor bolts.

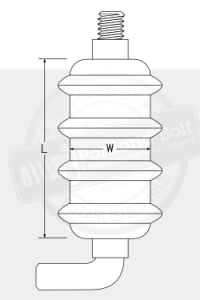

Dimensions

Contec offers anchor sleeves that cover a variety of anchor bolt diameters, while Wilson sleeves are used specifically with one diameter of anchor bolt. Contec sleeves are color coded per the diameter they are used with. Wilson sleeves are all black.

| Wilson Sleeves | Contec Sleeves | ||

|---|---|---|---|

| Bolt Size | Shell Size W x L | Color Code | Shell Size W x L |

| 1⁄2" | 2" x 5" | yellow | 2" x 5" |

| 3⁄4" | |||

| 5⁄8" | 2" x 7" | white | 2" x 7" |

| 3⁄4" | |||

| 7⁄8" | |||

| 1" | 3" x 10" | green | 3" x 10" |

| 11⁄4" | |||

| 11⁄2" | 4" x 15" | red | 4" x 15" |

| 13⁄4" | |||

| 2" | 4" x 18" | blue | 4" x 18" |

| 21⁄4" | |||

| 21⁄2" | 6" x 24" | brown | 6" x 24" |

| 3" | |||

| 4" | - | black | 6" x 24" |

| 5" | |||

Technical Information

The Contec and Wilson anchor sleeves both conform to the following technical specifications:

| Plastic: | High Density Polyethylene |

| Density, gms/cc: | ASTM D 1505-68 .956 |

| Vicat Softening Point °F: | ASTM D 1525-70 256°F / 124°C |

| Brittleness Temperature °F: | ASTM 746-70 -180°F / -118°C |

| Torch Application: | Slow Burn |

| Compression Test: | 180 psi / 12.7 kg/sq.cm |