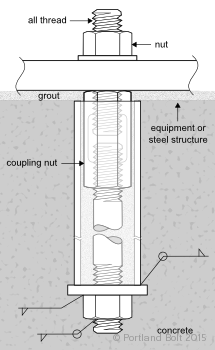

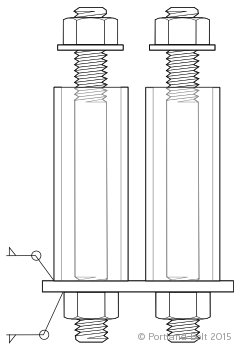

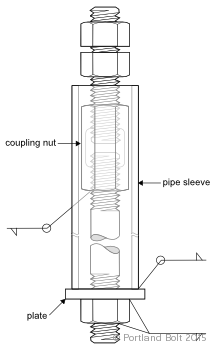

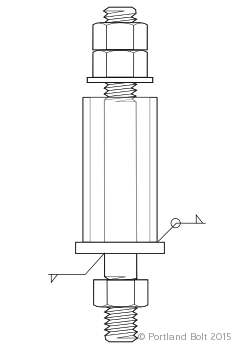

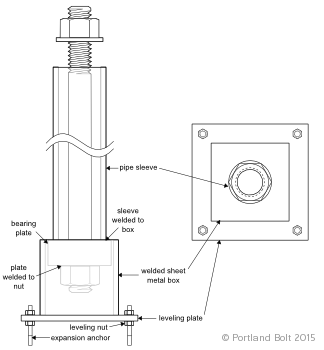

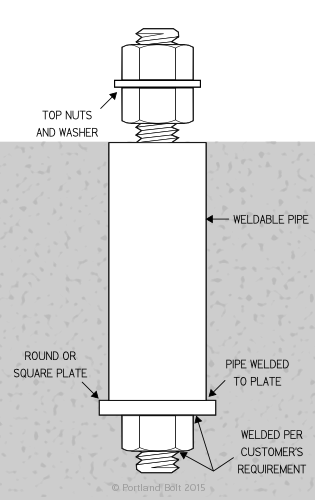

While plastic anchor sleeves offer a fast and cheap solution to alignment and placement of anchor bolts, some projects require custom fabricated pipe anchor sleeves due to the engineering requirements or just the intricate scope of a job. These typically complex welded pipe sleeves come in a variety of configurations, serve a variety of purposes, and are typically designed specifically per the job.

In instances where the an equipment manufacturer or structural engineer has prescribed that the anchor bolts will be preloaded or pretensioned, a pipe sleeve ensures that the concrete does not bond to the anchor bolt and prevent the anchor bolt from fully elongating. Full elongation along the full length of the anchor bolt can be especially important for equipment bases that have moving or vibrating equipment. Without a welded pipe sleeve it is very difficult to ensure that when the anchor bolts are tensioned that full elongation has been achieved and that the potential concrete bond to the anchor bolts is completely broken. This complex structural issue, along with the initial design of the assembly, must be completely handled and specified by a structural engineer.

Often these complicated assemblies will be for equipment foundations or other highly critical structure bases that require precise alignment to place the equipment or structure being fastened down to the foundation. Placement and alignment mistakes are simply not an option for these large projects where installation costs involving crews of workers and cranes vastly outweigh the initial costs of the welded pipe anchor sleeves. The repair and rework costs for a botched anchor bolt(s), or even the back charges or liquidated damages that could arise from project delays, for these type of projects can be very significant.

For these reasons choosing a qualified and trusted manufacturer for welded pipe anchor bolt sleeves is an extremely important decision which must weigh all the factors involved including quality, cost, lead time, and the reputation of the manufacturer.

Please click through a slideshow showing actual submittal drawings of welded pipe assemblies and some photos of the final product.